The Industry 4.0 era has exploded with opportunities for businesses, but it also comes with complex challenges. To thrive in today’s highly competitive environment, digitalization has become the key to success for all enterprises—especially those operating in the process industry.

Process industries must continuously make optimal design and operational decisions to ensure efficiency, cost savings, and sustainable value creation. However, making smart decisions based on complex data and numerous variables requires an advanced and comprehensive solution.

gPROMS – an advanced PROCESS MODELING AND SIMULATION system developed by Siemens – is designed to deeply capture manufacturing process data with high precision. It supports process design, simulation, and optimization of both design and operations quickly and efficiently. Tailored specifically for the process industries, gPROMS serves a wide range of sectors including Oil & Gas, Petrochemicals, Chemicals, Pharmaceuticals, Energy, and Wastewater Treatment.

.png)

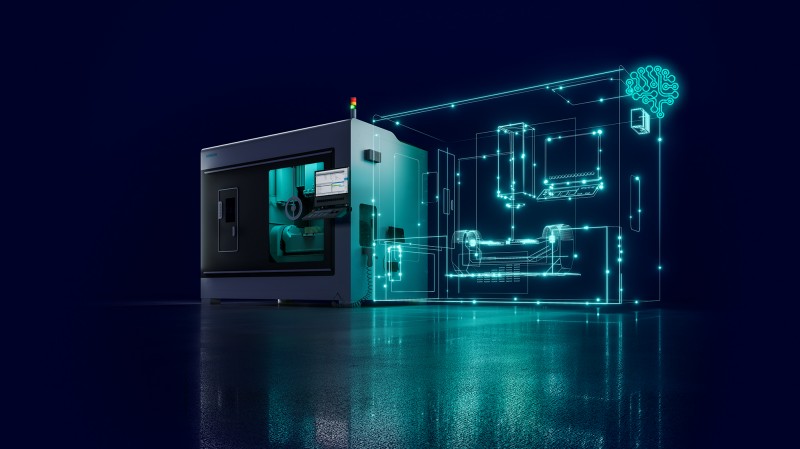

How does gPROMS leverage the power of Digital Twin to deliver real-world value?

gPROMS harnesses the vast potential of data and advanced algorithms, combined with the Digital Twin concept, to provide a comprehensive solution for the design, simulation, analysis, and optimization of processes and technical operations. This integration brings practical value to businesses across a wide range of industries by enabling smarter decision-making, improving efficiency, and enhancing operational performance.

.png)

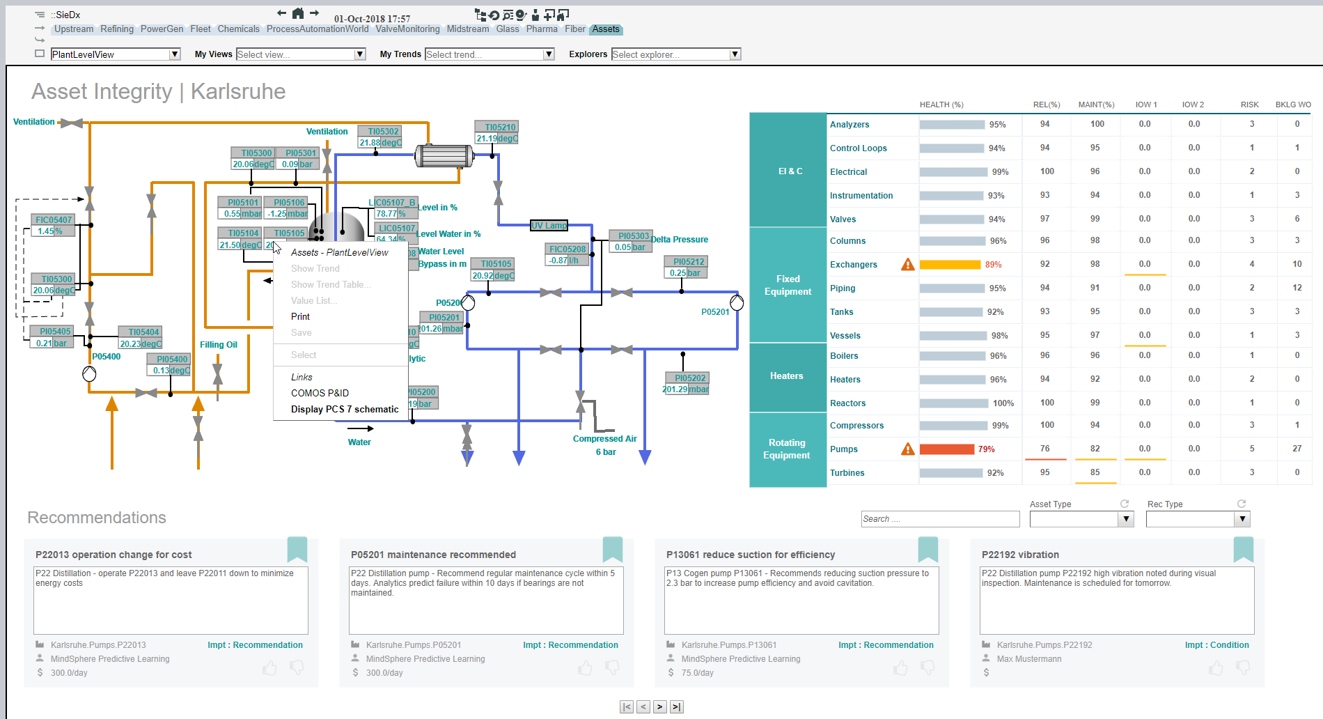

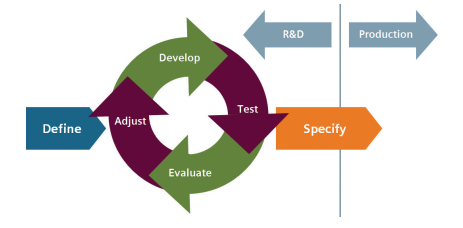

Siemens gPROMS – Comprehensive Support from R&D to Plant Operation

Siemens gPROMS is an advanced simulation solution that supports users throughout the entire process lifecycle—from the initial Research and Development (R&D) phase to full-scale plant operation. Equipped with cutting-edge tools within the most powerful modeling and optimization environment in the process industry, gPROMS delivers an Industry 4.0 experience that goes far beyond what traditional system design software can offer. It helps maximize profitability and efficiency while minimizing total operational costs, empowering businesses to make smarter, data-driven decisions at every stage.

.png)

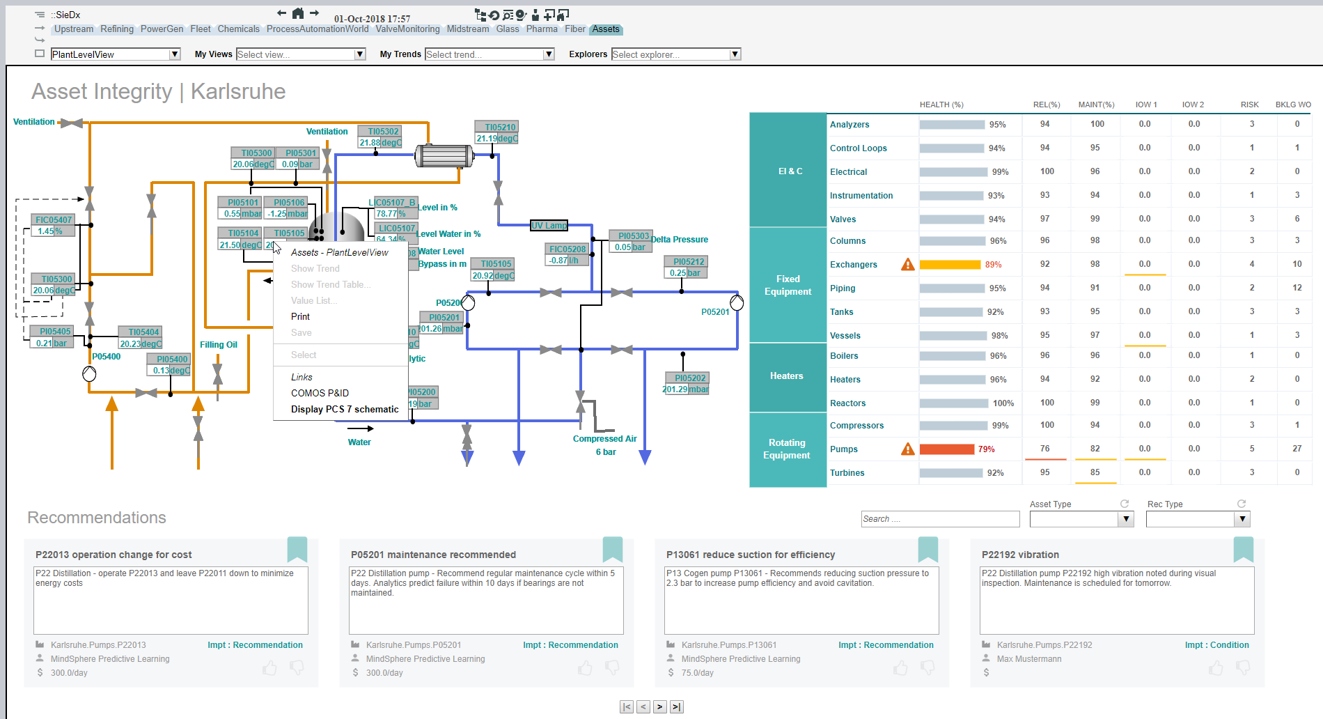

Key Features of Siemens gPROMS:

- Detailed and Accurate Modeling: Enables the creation of complex industrial process models, accurately simulating production workflows. This allows businesses to gain deeper insights into the factors that impact performance and product quality.

- Comprehensive Simulation and Analysis: Provides the ability to simulate operational scenarios and potential risks, helping businesses anticipate and prepare for unpredictable situations more effectively.

- Efficient Process Optimization:Integrates advanced optimization tools to enhance process design, reduce costs, and improve production efficiency. This capability empowers businesses to make precise, data-driven decisions based on model outputs.

- End-to-End Product Lifecycle Management:gPROMS supports full lifecycle management—from initial concept through to real-world operation—ensuring every stage of the production process is optimized for maximum performance and efficiency.

- Flexible Integration and Connectivity:Allows seamless integration with other software systems and real-time operational data, enabling continuous modeling and optimization throughout the production process.

Risk Assessment and Management:With its high-fidelity simulation capabilities, gPROMS helps businesses identify and evaluate potential risks. This facilitates the development of effective risk management strategies, ensuring safety and reliability in process operations.

Siemens gPROMS delivers outstanding benefits for businesses in the industrial sector:

- Enhanced Production Efficiency: By optimizing processes, gPROMS helps reduce costs and improve product quality, thereby increasing overall production efficiency.

- Risk Reduction:Detailed simulation and analysis enable businesses to effectively anticipate and manage risks, ensuring safe operations.

- Time and Cost Savings:The design and implementation of new processes are carried out more quickly and efficiently.

- Increased Competitiveness:Improved product quality and optimized operations help businesses maintain and enhance their competitive position in the market.

- Comprehensive Management:Supports end-to-end product lifecycle management, from concept to execution, ensuring continuity and efficiency in production activities.

A versatile modeling environment tailored to every need,gPROMS offers a comprehensive modeling ecosystem that meets the simulation and process optimization needs across various industries:

- gPROMS Process: Digital design and operation of high-performance processing plants

- gPROMS FormulatedProducts: Integrated digital design and production of solid materials

- gPROMS FuelCell: Optimal design of fuel cell components and systems

- gPROMS Flare: Integration of high-accuracy dynamic tools for analyzing process safety levels

- gPROMS Water: Design and optimization of water treatment processes

With its robust simulation and end-to-end process optimization capabilities, gPROMS is an essential tool that empowers businesses across industries to enhance operational efficiency, reduce costs, and strengthen their competitive edge.

🚀 gPROMS – The catalyst to accelerate your business in the digital era!

Contact ESTEC now for a free consultation on the gPROMS solution!