MCENTER - A reliable advanced machining digitization solution from Siemens.

MCENTER is an advanced solution from Siemens with a combination of advanced technologies such as numerical control system (CNC), automation, and data analysis, MCENTER offers the ability to improve efficiency and accuracy. during machining. The system integrates advanced software and hardware, allowing data collection and integration from various sources, including machining machines, gauges, sensors, and production management systems.

.png)

MCENTER focuses on optimizing production processes, ensuring consistency and efficiency in work. With MCENTER, machining programming is easier than ever. With the aid of advanced programming technologies such as G-code and M-code languages, operators can specify specific parameters and commands to perform machining processes accurately and efficiently. fruit.

Furthermore, MCENTER integrates Siemens' most advanced numerical control system such as SINUMERIK 840D SL. With this control system, the operator has precise control over the moving axes and machining functions, while ensuring flexibility and reliability.

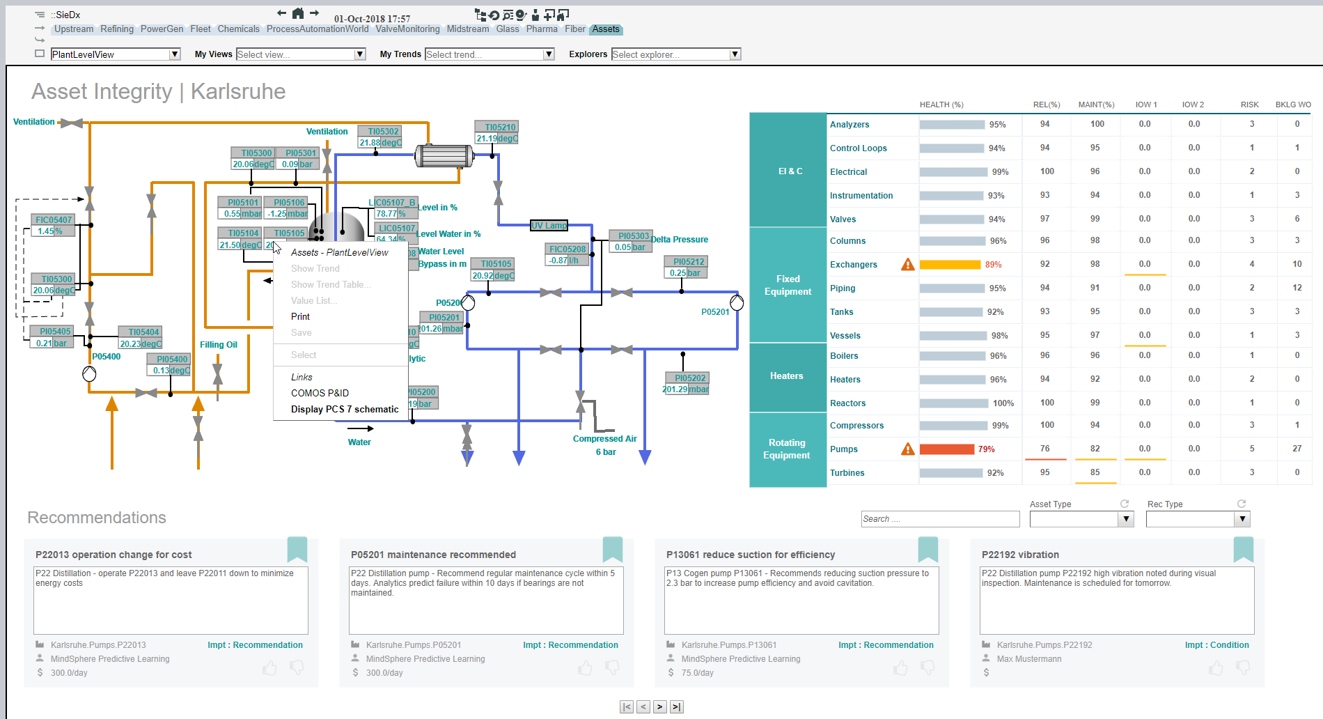

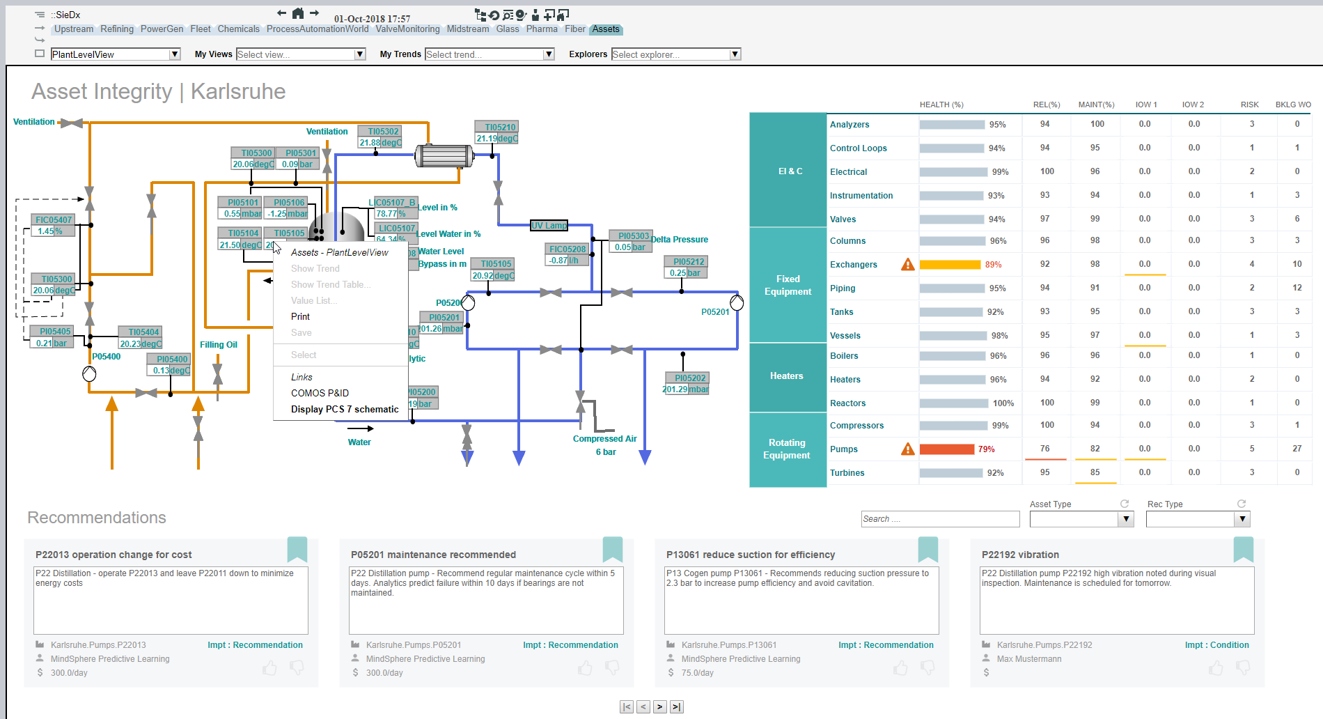

Using MCENTER, users can collect and analyze information from the machining process to understand machine performance, condition and find ways to improve production processes. The built-in artificial intelligence and data analytics technologies in MCENTER help intelligently and automatically organize data, thereby yielding important information for smart and efficient decision making.

Not only focusing on the machining process, MCENTER also integrates production management systems and project management systems. This helps create consistency and interoperability across various manufacturing processes, from machining programming and materials management to monitoring and data analysis. The integration of these systems helps to create a powerful, efficient and time-saving production process.

.jpg)

Where is the shopfloor platform Mcenter used?

Mcenter supports different use cases on the shopfloor. Here are a few examples.

1.Tool Management:Quản Lý Công Cụ Gia Công Với Manage Myresources/Tools Của Siemens

2. Program Management:Quản Lý Chương Trình Gia Công Với Manage Myresources/Programs Siemens

3. Overall Equipment Effectiveness (OEE):Quản Lý Hiệu Suất Máy Gia Công Với Analyze Myperformance/Oee Siemens

ESTEC is Siemens' authorized partner in Vietnam, providing consulting, implementation and technical support services for MCENTER solutions. We have a team of experienced experts in MCENTER solution implementation, from hardware and software provision, to training and after-sales support. We are committed to accompanying you in the digital transformation and optimization of the machining process.

Please contact us for more detailed advice:

Contact Info:

Hotline: (+84) 28 8886 8799

Email: sales@biendongco.vn