FLENDER MECHANICAL DRIVE SYSTEM

FLENDER MECHANICAL DRIVE SYSTEM

FLENDER is a well-known manufacturer of Couplings and Gearboxes. Founded in 1899 in Germany, FLENDER had 120 years of building and asserting its brand in the field of drive technology.

Since 2005 when it was merged with Siemens, it has helped Flender expand its product distribution network to 190 countries worldwide.

In Vietnam, ESTEC is an authorized distributor of FLENDER on Mechanical Drive System, including: Gearboxes, Couplings.

FLENDER MECHANICAL DRIVE SYSTEM

In the era of Industry 4.0, smart manufacturing requires your factory to have a modern production line. Each stage of production must be linked together to ensure continuous performance, fast with high accuracy, providing quality products to customers.

One of the “powerful arms” that cannot be absent in most production lines is the Mechanical Drive System.

FLENDER is a well-known manufacturer of Couplings and Gearboxes. Founded in 1899 in Germany, FLENDER had 120 years of building and asserting its brand in the field of drive technology. FLENDER has a global network of factories: Germany, France, USA, India, China.

Since 2005 when it was merged with Siemens, it has helped Flender expand its product distribution network to 190 countries worldwide.

In Vietnam, ESTEC is an authorized distributor of Flender on Mechanical Drive System, including: Gearboxes, Couplings.

WHAT IS MECHANICAL DRIVE SYSTEM?

Mechanical Drive System are installed on most manufacturing machines, production lines, conveyors and factory automation systems.

This is the transmission part of the industrial machine - the “heart” to operate the production process at the factory, which connects the machine's components, supporting the system to operate smoothly and stably.

CLASSIFICATION AND APPLICATION

FLENDER Mechanical Drive System have good quality, durability and high reliability. With a wide range of products, FLENDER provides comprehensive solutions for powertrains, which can meet basic applications and even applications requiring specific features and specialized techniques.

Nowadays, FLENDER products can be applied to almost industries across the globe, from light industry to heavy industry: Food & Beverage, Power, Cement, Steel, Sugar, Pulp & Paper, Fertilizers, Chemicals, Pumping/Crane System, ... and many other industries.

1. Product group of FLENDER Gearboxes

FLENDER Gear Boxes are designed for compact size but torque is always higher than rivals of the same size. This advantage offers maximum flexibility in designing various models and production lines; thus can work well under severe impacts, ensuring high efficiency and absolute reliability.

FLENDER offers a wide range of different industrial Gear Boxes, which can be installed in horizontal or vertical directions, perpendicular axes, straight shafts or helical bevel gear, including:

- FLENDER FZG Standard

- Specifications:

+ Compact design

+ Installed horizontally, perpendicular to the output shaft options, varied from positive shaft using fixed spindle, negative shaft flange, ... to help increase usage efficiency.

+ 4-speed reduction gearbox, torque range up to 1,400 kNm, corresponding to a capacity of 4,500Kw.

With these characteristics, FZG Standard is confirmed as one of the most efficient gearboxes on the market, meeting most of the basic requirements in today's industries.

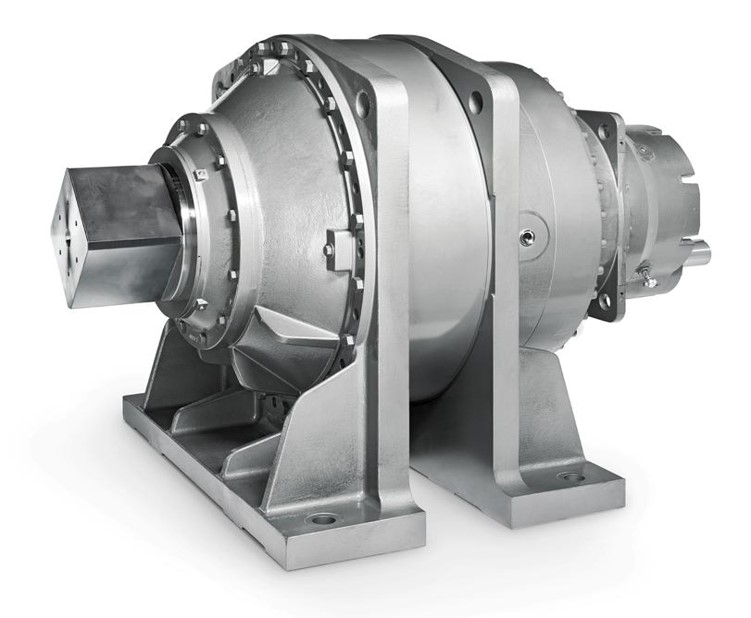

- FLENDER PLANUREX

- Specifications:

+ Design with 5 basic designs: Planetary gearboxes have 2 or 3 levels or are combined with cylindrical gearboxes/bevel-type gears/worm gears/screw gears/screw gears to with transmission ratio up to 4000: 1.

+ Compared with the standard FZG series, PLANUREX can meet the range of rated power and higher torque up to 4,700 kNm.

+ PLANUREX is standardized and supports sizes up to 30 sizes.

From a technical perspective, the characteristics of PLANUREX are superior to other products thanks to the large capacity corresponding to light weight, high performance and minimizing noise during operation. With these outstanding advantages, PLANUREX is widely applied in many industries around the world.

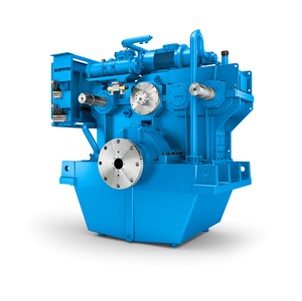

- FLENDER DUORED

- Specifications:

+ The size is minimized to help save the maximum space.

+ Range of torque up to 4,800 kNm, corresponding to capacity of 10,000 Kw.

With these features, DUORED is designed to optimize noise reduction and save energy, widely applied in the sugar industry.

Some gearboxes with special designs (Special Gearboxes):

.jpg)

Complete Drive Systems for Conveyor Belts

.jpg)

Bevel helical gear units in cooling tower

_jpg.png)

Vertical Roller Mills for Cement

2. FLENDER Couplings

Coupling is a device that plays an intermediary role in connecting the axes together, serving the task of moving the motion from the drive shaft (motor, reducer) to the axis of the industrial machine (conveyors, water pumps, fan, …). In addition, the coupling also works to prevent overload, reduce dynamic load, compensate for center commands between axles.

FLENDER Couplings are used in almost every industry, from basic standard applications to specialized applications.

As one of the world’s leading suppliers in the field of transmission, FLENDER offers a wide range of couplings of various types and sizes, torque ranges up to 10,000 kNm, including:

- Flexible couplings

N-EUPEX

BIPEX

RUPEX COUPLINGS

- Highly flexible couplings

ELPEX-B

ELPEX-S

- Hydrodynamic couplings

FLUDEX COUPLINGS

- Torsionally rigid couplings

ARPEX

ZAPEX

ESTEC provides Mechanical Drive System from FLENDER with high quality and reliability. Besides, we also focus on after sales service to customers.

Our experienced and highly qualified engineers team are always ready to assist customers during the product warranty period according to the manufacturer’s regulations, ensuring the factory always operates stably.

Projects were implemented by ESTEC

- Upgrade Rotary Kiln Gearbox at INSEE Honchong Factory - Kien Giang

.jpg)

.jpg)

- Repairing Vertical Crushing Box at Ha Tien - Phu Huu Cement Factory

.jpg)

.jpg)

Please contact us immediately for detailed consultation and quotation about the most suitable product for the customer’s factory operation system.