SOME TYPICAL COUPLINGS

SOME TYPICAL COUPLINGS

| Flexible couplings |

Claw couplings |

| Highly flexible couplings | Rubber tyre couplings Rubber disk couplings |

| Hydrodynamic couplings | Fluid couplings |

| Torsionally rigid couplings | Gear couplings All-steel couplings |

SOME TYPICAL COUPLINGS

1.Flexible Couplings: Flexible Flender couplings have a wide range of possible applications. A broad standard modular system as well as specially designed application-specific coup[1]lings are available.

N-EUPEX cam couplings Rated torque: 19 Nm … 62,000 Nm,

RUPEX RUPEX pin-and-bush couplings Rated torque: 200 Nm … 1,300,000 Nm

N-BIPEX N-BIPEX cam couplings Rated torque: 12 Nm … 4,650 Nm

2. Highly Flexible Couplings ELPEX®: couplings are free of circumferential back-lash. Their damping capacity and low torsional stiff-ness make them especially well-suited for coupling machines with strongly non-uniform torque characteristics or large shaft misalignment.

- ELPEX elastic ring couplings Rated torque: 1,600 Nm … 90,000 Nm

- ELPEX-B elastic tire couplings Rated torque: 24 Nm … 14,500 Nm

- ELPEX-S rubber disk couplings Rated torque: 330 Nm … 63,000 Nm

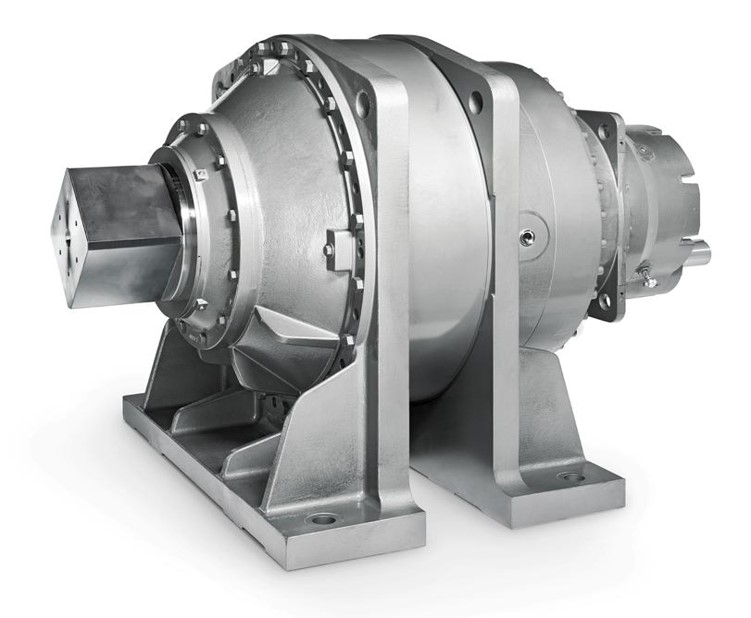

3.Torsionally rigid couplings

For transmission of high torques, we offer both ARPEX all-steel couplings and ZAPEX gear couplings in a range of versions. Their purposes of application vary accor[1]ding to specific requirements with respect to shaft misalignment, temperature and torque.

ZAPEX gear couplings Rated torque: 1,300 Nm … 7,200,000 Nm

ARPEX high Performance Couplings Rated torque: 1,000 Nm … 588,500 Nm

N-ARPEX and ARPEX all-steel couplings Rated torque: 92 Nm … 2,000,000 Nm

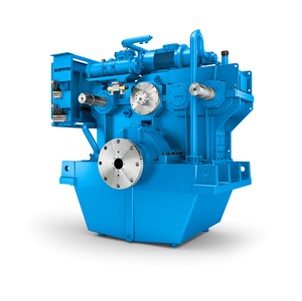

4. Hydrodynamic couplings: The FLUDEX hydrodynamic fluid coupling works accor[1]ding to the Föttinger principle. It functions entirely free of wear.

FLUDEX hydrodynamic fluid coupling works accor[1]ding to the Föttinger principle. It functions entirely free of wear.

5. Application-specific couplings Couplings for rail vehicles must meet high demands. Due to their high degree of stan[1]dardization and wide variety, they can be used in the most diverse vehicle types.

- Railway coupling Rated torque: 1,000 Nm … 9,500 Nm. Each wind turbine coupling is designed to optimally meet the requirements of the respective wind turbine. The coupling connects the fast-running gear shaft with the generator shaft and is available for wind turbines with a capacity of up to 12 MW.

- Wind turbine couplings Rated torque: 10,000 Nm … 60,000 N

6. Flexible Couplings: Flexible Flender couplings have a wide range of possible applications. A broad standard modular system as well as specially designed application-specific coup[1]lings are available.

- N-EUPEX cam couplings Rated torque: 19 Nm … 62,000 Nm,

- RUPEX RUPEX pin-and-bush couplings Rated torque: 200 Nm … 1,300,000 Nm

- N-BIPEX N-BIPEX cam couplings Rated torque: 12 Nm … 4,650 Nm

7. Highly Flexible Couplings ELPEX®: couplings are free of circumferential back-lash. Their damping capacity and low torsional stiff-ness make them especially well-suited for coupling machines with strongly non-uniform torque characteristics or large shaft misalignment.

- ELPEX elastic ring couplings Rated torque: 1,600 Nm … 90,000 Nm

- ELPEX-B elastic tire couplings Rated torque: 24 Nm … 14,500 Nm

- ELPEX-S rubber disk couplings Rated torque: 330 Nm … 63,000 Nm

8. Torsionally rigid couplings

For transmission of high torques, we offer both ARPEX all-steel couplings and ZAPEX gear couplings in a range of versions. Their purposes of application vary accor[1]ding to specific requirements with respect to shaft misalignment, temperature and torque.

- ZAPEX gear couplings Rated torque: 1,300 Nm … 7,200,000 Nm

- ARPEX high Performance Couplings Rated torque: 1,000 Nm … 588,500 Nm

- N-ARPEX and ARPEX all-steel couplings Rated torque: 92 Nm … 2,000,000 Nm

9. Hydrodynamic couplings: The FLUDEX hydrodynamic fluid coupling works accor[1]ding to the Föttinger principle. It functions entirely free of wear.

FLUDEX hydrodynamic fluid coupling works accor[1]ding to the Föttinger principle. It functions entirely free of wear.

10. Application-specific couplings Couplings for rail vehicles must meet high demands. Due to their high degree of stan[1]dardization and wide variety, they can be used in the most diverse vehicle types.

- Railway coupling Rated torque: 1,000 Nm … 9,500 Nm. Each wind turbine coupling is designed to optimally meet the requirements of the respective wind turbine. The coupling connects the fast-running gear shaft with the generator shaft and is available for wind turbines with a capacity of up to 12 MW.

- Wind turbine couplings Rated torque: 10,000 Nm … 60,000 N

| Coupling type | Pin coupling, flexible |

| Features | Fail-safe, torsionally flexible, damping |

| Nominal torque | 19 Nm to 62,000 Nm |

| Perm. peripheral speed | 36 m/s |

| Temperature range | –50°C to +100°C |

| Perm. angular misalignment | 0.2° |

| Designs |

Available from the standard range: with spacer, with brake disk/drum, for vertical mounting position, Optionally available: with Taper bush, with SAE connection |

|

Examples of application |

Pumps, compressors, fans, blowers |

| Coupling type | Pin-and-bush coupling, flexible |

| Features | fail-safe, torsionally flexible, damping |

| Nominal torque | 200 Nm to 1,300,000 Nm |

| Perm. peripheral speed | 40/60 m/s |

| Temperature range | –50°C to +100°C |

| Perm. angular misalignment | 0.2° |

| Designs |

Available from the standard range: with brake disk/drum, for vertical mounting position, acc. to directive 94/9/EC Optionally available: with Taper bush, with clamping hub, with spacer, with SAE connection, with axial play limiting device, as disengaging coupling, as shear pin coupling, |

| Examples of application | Pumps, compressors, rotary kilns, cement mills |

| Coupling type | Fluid coupling, hydrodynamic |

| Features | With operating slip, hydrodynamic |

| Nominal power rating | 0.5 kW to 2,500 kW |

|

Perm. peripheral speed |

80 m/s |

| Temperature range | –40°C to +50°C |

| Perm. angular misalignment | 0.2° |

| Designs |

Available from the standard range: with spacer, with brake disk/drum, for vertical mounting position, |

| Examples of application | Conveying belts, mixers, crushers, fans/blowers |